T300

Details

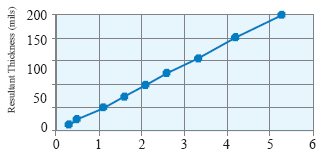

T-PAD300 has an ideal filler blend that gives it a low-modulus characteristic that maintains optimal thermal performance yet still allows for easy handling.The natural tack on both sides of the material allows for good compliance to adjacent surfaces of components, minimizing interfacial resistance. Note: Resultant thickness is defined as the final gap thickness of the application.

|

T-PAD300 |

|

|

|

|

PROPERTY |

IMPERIAL VALUE |

METRIC VALUE |

TEST METHOD |

|

Color |

Black |

Black |

Visual |

|

Reinforcement Carrier |

— |

— |

— |

|

Thickness (inch) / (mm) |

0.020 to 0.200 |

0.508 to 5.080 |

ASTM D374 |

|

Inherent Surface Tack (1- or 2-sided) |

2 |

2 |

— |

|

Density (g/cc) |

2.1 |

2.1 |

ASTM D792 |

|

Heat Capacity (J/g-K) |

1.0 |

1.0 |

ASTM E1269 |

|

Hardness, Bulk Rubber (Shore 00) (1) |

40 |

40 |

ASTM D2240 |

|

Young’s Modulus (psi) / (kPa) (2) |

45 |

310 |

ASTM D575 |

|

Continuous Use Temp (°F) / (°C) |

-76 to 392 |

-60 to 200 |

— |

|

ELECTRICAL |

|

|

|

|

Dielectric Breakdown Voltage (Vac) |

>6000 |

>6000 |

ASTM D149 |

|

Dielectric Constant (1000 Hz) |

5.5 |

5.5 |

ASTM D150 |

|

Volume Resistivity (Ohm-meter) |

10“ |

10“ |

ASTM D257 |

|

Flame Rating |

V-O |

V-O |

U.L. 94 |

|

THERMAL |

|

|

|

|

Thermal Conductivity (W/m-K) |

1.5 |

1.5 |

ASTM D5470 |

Next:G8000